![]()

![]()

![]()

Slag Paver Block

Slag Paver Block

Overview

| Product Idea and description |

|

| Target group |

|

| Raw material required |

|

| Production capacity, facility and labour required |

|

| Production Process |

|

| Tools &Equipment’s required for production and prices |

|

| Financial linkages/ Government schemes | Regional Banks or FIs PMEGP, SIDBI, CLCSS etc. |

| Pricing Strategy | INR15-20 per piece according to shape, type or variety(~13% margin) |

| Package, storage and transportation requirements |

|

| Marketing strategy | Estimate of Market size in India

|

| Distribution Channel |

|

Production stage

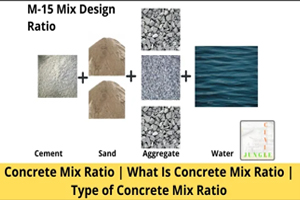

Raw Material Proportioning- The proportion of cement:sand: slag for manufacturing paver block should be 1:4:4 & water quantity depend upon mixing condition. Mixer is rotated for arounf 15-20 min.

Mixing-Concrete Mixer should be used for better bonding between above proportion.

Compacting-Vibrating table is being for compacting or eliminating water bubbles in the product

Curing & Drying-After pouring into mould boxes the block is left into direct sunlight for 24 hours drying. The block thus hardening are cured with water to permit moisturisation or settling of cement for next 20 days.

Product SWOT Analysis

|

Strengths |

Weaknesses |

Opportunities |

Threats |

|

|

|

|

Financial Plan

To start the slag paver block manufacturing business with working capital requirement (raw material, and labour etc) at 16.50L per month and per unit product cost at around INR15-20.Working capital requirement would be 16.50L per month assuming working capital cycle 30days and total 8 work hours in a day.

Summery Sheet:

| S.No | Parameters | Value (INR) |

| 1 | Fixed cost | 2083950 |

| 2 | Working capital | 8052000 |

| 3 | Total capital investment | 10135950 |

| 4 | Total cost of investment | 9430209 |

| 5 | Sales | 10800000 |

| 6 | Net profit | 12.68 |

| 7 | ROI | 13.51 |

|

Fixed cost |

||

|

S.No |

Parameters |

Total Value |

|

1 |

Land & Building |

1000000 |

|

Machinery & equipment |

||

|

2 |

Concrete Mixer & Vibrating Table, accessories |

135000 |

|

3 |

Slag Crusher |

100000 |

|

4 |

Plastic Mould (10000 Nos.) |

700000 |

|

5 |

Pump set & water tank |

9500 |

|

6 |

Electrification & Installation @10 % cost of machinery |

94450 |

|

7 |

Pre-operative expense |

10000 |

|

8 |

Total cost of machinery & equipment |

1048950 |

|

9 |

Cost of office equipment |

35000 |

|

10 |

Total cost of machinery & office |

1083950 |

|

11 |

Total fixed cost |

2083950 |

|

Working capital |

||||

|

S.No |

Parameters |

Nos. |

INR/Unit |

Total Value |

|

1 |

Workers |

16 |

8000 |

128000 |

|

2 |

Accountant |

1each |

20000 |

40000 |

|

3 |

Total Manpower cost |

168000 |

||

|

Raw material & utilities |

||||

|

4 |

Raw Material |

450000 |

||

|

5 |

Utility Per month |

20000 |

||

|

6 |

Water |

1500 |

||

|

7 |

Total cost of raw material & Utilities |

471500 |

||

|

Other contingent expenses |

||||

|

8 |

Repair & maintenance |

5000 |

||

|

9 |

Transportation |

2500 |

||

|

10 |

Telephone |

2000 |

||

|

11 |

Other consumable |

1000 |

||

|

12 |

Advertisement & publicity |

2000 |

||

|

13 |

Postage & stationary |

1500 |

||

|

14 |

Insurance |

15000 |

||

|

15 |

Miscellaneous expenses |

2500 |

||

|

16 |

Total of other contingency |

31500 |

||

|

17 |

Grand total of working capital/month |

671000 |

||

|

18 |

Grand total of working capital for 12 month |

8052000 |

||

|

Financial Analysis |

||||

|

S.No |

Parameters |

Nos. |

INR per Unit |

Value |

|

1 |

Total recurring cost |

8052000 |

||

|

2 |

Depreciation of building@ 5% |

50000 |

||

|

3 |

Depreciation of machinery@ 10% |

104895 |

||

|

4 |

Depreciation of office equipment @ 20% |

7000 |

||

|

5 |

Interest on Total capital investment @12 % |

1216314 |

||

|

6 |

Total cost of Investment |

9430209 |

||

|

7 |

Sales/ turn over per year |

6L pieces/year |

INR 18/piece |

10800000 |

|

8 |

Net profit ( sales- cost of production) |

1369791 |

||

|

9 |

Net profit ratio |

Net profit*100/sale |

12.68 |

|

|

10 |

Return on Investment |

Net profit*100/Total capital investment |

13.51 |

|