![]()

![]()

![]()

![]()

![]()

![]()

Bamboo Bathroom Fitting Items

Overview

| Product Idea and description |

|

| Target group |

|

| Raw material required |

|

| Production capacity, facility and labour required |

|

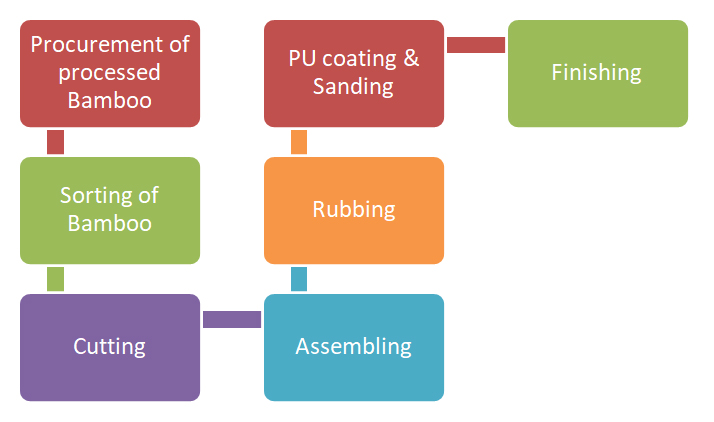

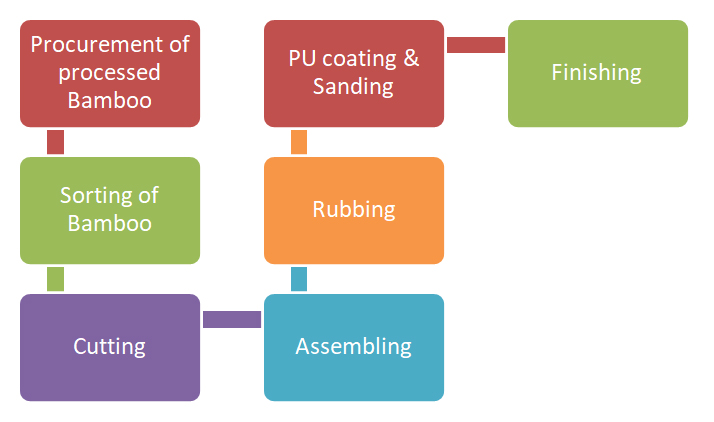

| Production Process |

|

| Tools &Equipment’s required for production and prices |

These are the customize tools required for production, if want to go for automation then more sets of equipment required. |

| Financial linkages/ Government schemes | National Bamboo Mission to support enterprise PMEGP, SIDBI |

| Pricing Strategy | Rs. 3500 (30% profit) |

| Package, storage and transportation requirements |

|

| Marketing strategy | Estimate of Market size in India and globally Globally- The global ceramic sanitary ware market size is projected to grow from USD 32.1 billion in 2020 to USD 44.6 billion by 2025, at a CAGR of 6.8%. Major B2B & B2C Portals – exportsindia.com, alibaba.com, indiamart.com, amazon.com, Major suppliers– there is no any major supplier of Bamboo Sanitary fitting in India

|

| Distribution Channel |

|

Production stage

Product SWOT Analysis

|

Strengths |

Weaknesses |

Opportunities |

Threats |

|

|

|

|

Financial Plan

To start the bamboo bathroom fitting items manufacturing business, one can invest 15.52L INR with a working capital requirement of 8.65L INR per month, assuming the working capital cycle is 25 days and runs for a total of 8 work hours in a day.

| S.No | Parameters | Unit | Value |

| 1 | Capital Cost | INR | 1552800 |

| 2 | Working Capital | INR | 10380000 |

| 3 | Total Cost of Investment | INR | 11932800 |

| 4 | Sales | INR | 21600000 |

| 5 | Gross profit | INR | 9667200 |

| 6 | Tax @ 30% | INR | 2900160 |

| 7 | Net Profit | INR | 6767040 |

| 8 | Pay Back Period (Total Investment/Net Profit*12) | Months | 21 |

| S.No | Parameters | Value |

| 1 | Land & Building | 800000 |

| Machinery & equipment | ||

| 2 | Angle Grinder (8 No.) | 80000 |

| 3 | Sanding Belt (40 No.) | 200000 |

| 4 | Drill Machine (4 No.) | 40000 |

| 5 | Mini Lathe Machine (4 No.) | 280000 |

| 6 | Spray Machine (4 No.) | 20000 |

| 7 | Cutting Machine (4 No.) | 28000 |

| 8 | Electrification & Installation @ 10% cost of machinery | 64800 |

| 9 | Pre-Operative Expense | 5000 |

| 10 | Cost of Office Equipment | 35000 |

| 11 | Total Capital Cost | 1552800 |

|

S.No |

Parameters |

INR/Unit |

Value |

|

1 |

Workers (20 No.) |

8000 |

160000 |

2 |

Accountant (1 No.) | 12000 |

12000 |

|

3 |

Manager (1 No.) |

15000 |

15000 |

|

Raw Material & Utilities |

|||

|

3 |

Raw Material |

600000 |

|

|

4 |

Utility per Month |

20000 |

|

|

5 |

Water |

5000 |

|

|

Other Contingent Expenses |

|||

|

6 |

Repair & Maintenance |

5000 |

|

|

7 |

Transportation |

10000 |

|

|

8 |

Telephone |

2000 |

|

|

9 |

Other Consumables |

10000 |

|

|

10 |

Advertisement & Publicity |

7000 |

|

|

11 |

Postage & Stationary |

1500 |

|

|

12 |

Insurance |

15000 |

|

|

13 |

Miscellaneous Expenses |

2500 |

|

|

14 |

Grand Total of Working Capital (1 Year) |

10380000 |

|

|

S.No |

Parameters |

Unit |

Value |

|

1 |

Production per Month |

Pieces |

600 |

|

2 |

Selling Price per Product |

INR |

3000 |

|

3 |

Turnover per Month |

INR |

1800000 |

|

4 |

Annual Turnover |

INR |

21600000 |