![]()

![]()

![]()

![]()

![]()

![]()

Face Mask

Overview

| Product Idea and description |

|

| Target group |

|

| Raw material required |

|

| Production capacity (No’s) |

|

| Labour Required (Nos.) |

|

| Production Process |

|

| Tools & Equipment’s required for production and prices |

|

| Financial linkages/ Government schemes |

|

| Pricing Strategy |

|

| Package, storage and transportation requirements |

|

| Marketing strategy | The global face mask market size was valued at $1,523.0 million in 2019, and is estimated to reach $ 2,455.4 million by 2027 with a CAGR of 4.4% from 2021 to 2027. Furthermore, the outbreak of respiratory infection based pandemic diseases like H1N1 and COVID19 fuel the demand for face mask among frontline health workers and as well as general public, therefore significantly boosting the sales of face masks in the market. Major Suppliers- 3M, Healthkart, 1MG, Netmeds, etc. Marketing strategy:

|

| Distribution Channel |

|

Production stage

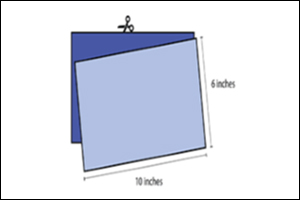

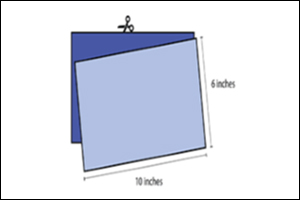

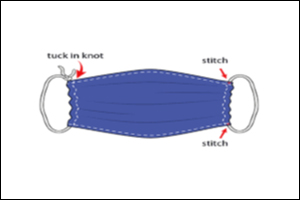

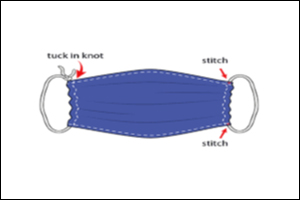

Fold over the long sides ¼ inch and hem. Then fold the double layer of fabric over ½ inch along the short sides and stitch down

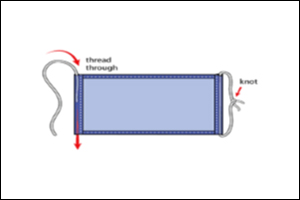

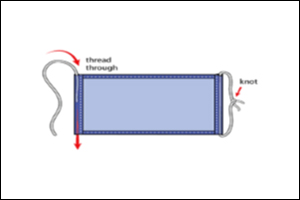

Run a 6-inch length of 1/8-inch wide elastic through the wider hem on each side of the mask. These will be the ear loops. Use a large needle or a bobby pin to thread it through. Tie the ends tight.

Don’t have elastic? Use hair ties or elastic head bands. If you only have string, you can make the ties longer and tie the mask behind your head.

Gently pull on the elastic so that the knots are tucked inside the hem. Gather the sides of the mask on the elastic and adjust so the mask fits your face. Then securely stitch the elastic in place to keep it from slipping.

Product SWOT Analysis

|

Strengths |

Weaknesses |

Opportunities |

Threats |

|

|

|

|

Financial Plan

| S.No | Parameters | Unit | Value |

| 1 | Capital Cost | INR | 261300 |

| 2 | Working Capital | INR | 942000 |

| 3 | Total Cost of Investment | INR | 1203300 |

| 4 | Sales | INR | 2880000 |

| 5 | Gross profit | INR | 1676700 |

| 6 | Tax @ 30% | INR | 503010 |

| 7 | Net Profit | INR | 1173690 |

| 8 | Pay Back Period (Total Investment/Net Profit*12) | Months | 12 |

| S.No | Parameters | Value |

| 1 | Land & Building | 200000 |

| Machinery & equipment | ||

| 2 | Sewing Machine (3 No.) | 30000 |

| 3 | Hand Tools | 2000 |

| 4 | Other Accessories | 1000 |

| 5 | Electrification & Installation @ 10% cost of machinery | 3300 |

| 6 | Pre-Operative Expense | 5000 |

| 7 | Cost of Office Equipment | 20000 |

| 8 | Total Capital Cost | 261300 |

|

S.No |

Parameters |

INR/Unit |

Value |

|

1 |

Workers (4 No.) |

8000 |

32000 |

|

2 |

Manager (1 No.) |

15000 |

15000 |

|

Raw Material & Utilities |

|||

|

3 |

Raw Material |

16000 |

|

|

4 |

Utility per Month |

2000 |

|

|

Other Contingent Expenses |

|||

|

5 |

Transportation |

1000 |

|

|

6 |

Telephone |

1000 |

|

|

7 |

Other Consumables |

2000 |

|

|

8 |

Advertisement & Publicity |

5000 |

|

|

9 |

Postage & Stationary |

500 |

|

|

10 |

Insurance |

3000 |

|

|

11 |

Miscellaneous Expenses |

1000 |

|

|

12 |

Grand Total of Working Capital (1 Year) |

942000 |

|

S.No | Parameters | Unit | Value |

1 | Production per Month | Pieces | 2000 |

2 | Selling Price per Product | INR | 120 |

3 | Turnover per Month | INR | 240000 |

4 | Annual Turnover | INR | 2880000 |